Selection of Multiple Sites

Large-scale logistics and processing operations face a tough problem in determining how to structure their networks. Enhancing processing and logistics networks so that goods can move from sources to destinations at low cost can increase profitability. However, adding facilities (or continuing to operate existing facilities) is costly as well.

Ploughman Analytics can help firms analyze the tradeoff between the lower freight costs made possible by the presence of processing or logistics nodes and the costs of these nodes themselves. For example, the construction cost of a new corn ethanol plant may easily exceed 100 million USD. If an enterprise is considering multiple investments of this magnitude, careful consideration of not just each facility, but each facility as the part of a network, can dramatically enhance profitability.

Ploughman can help clients select multiple locations and network configurations, helping to answer key questions: What volumes of material should go to or from each facility? Should new facilities be purchased or built? Should existing faculties be reduced or closed? We offer a comprehensive and systematic approach to considering large numbers of combinations, and can work with clients to optimize their logistics networks. Our team is adept at finding elegant solutions to problems in this class, given sets of locations and the client’s areas of concern.

- Ploughman takes into account road network time and shipping costs, prices at the source and destination facilities, and processing or handling capacity.

- Our approach examines different combinations of routing to minimize costs and maximize performance of the network.

- Different scenarios can be compared rapidly to sift out the better performing arrangements. Particularly when there are a large number of customer or supplier locations relative to the client facilities, this can greatly improve business operations by minimizing travel and removing unnecessary routes or facilities.

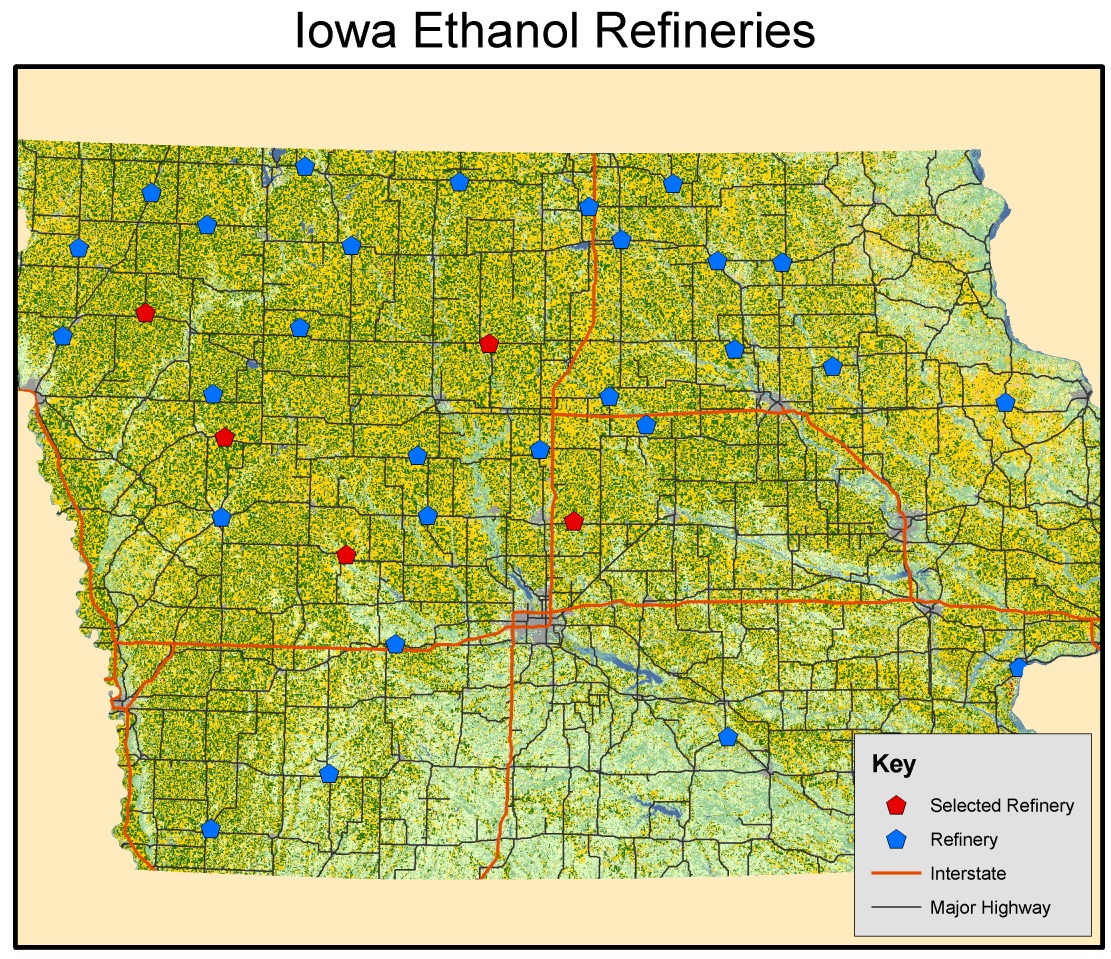

As an illustration, consider the set of ethanol refineries in the state of Iowa. A major firm considering acquiring, expanding, constructing, closing, or maintaining some number of facilities of this sort faces a potentially bewildering combination of alternatives to evaluate, and the illustrative map below represents one of a large number of selections of facilities from a current set. Ploughman Analytics can help major firms systematically evaluate these extremely large numbers of alternative network configurations.

The strength in our approach allows us not only to optimize for an existing set of facilities, but to determine which subset of facilities should be chosen among a pool of many possible candidates. Choosing certain locations will affect the viability of nearby locations, and these related effects vary depending on the factors that the client wants to minimize or optimize. Ploughman can harness tremendous processing power to tackle large scale problems and evaluate all possible combinations rather than merely a pre-picked set. This extends to situations where the client does not know how many facilities will be needed – the ideal number of facilities to build, alter, or remove can be a part of our solution.

Combined, Ploughman’s tools offer a comprehensive solution to a complex and multilayered problem. Limiting an evaluation to only pre-selected combinations might result in the analyst overlooking a better alternative solution - our computational and analytical expertise can examine every scenario to find the optimal solution for our clients.

When the average price to construct a single plant producing 100 million gallons of ethanol annually is 120 million USD, Ploughman Analytics’ ability to systematically analyze network investments can mean the difference between profitability and enterprise failure.

Ploughman Analytics, Inc.

3309 Cypress Creek Road

Champaign, IL 61822

(217) 693-4000